Tandem dies in cold forming: Structure, application and advantages

What is a tandem die?

In a conventional transfer die, all forming processes – such as cutting, drawing, punching or reshaping – are integrated into a single die set within one press. The part passes through the individual stages within the die set and is transported further by integrated transfer systems in what is called a transfer press.

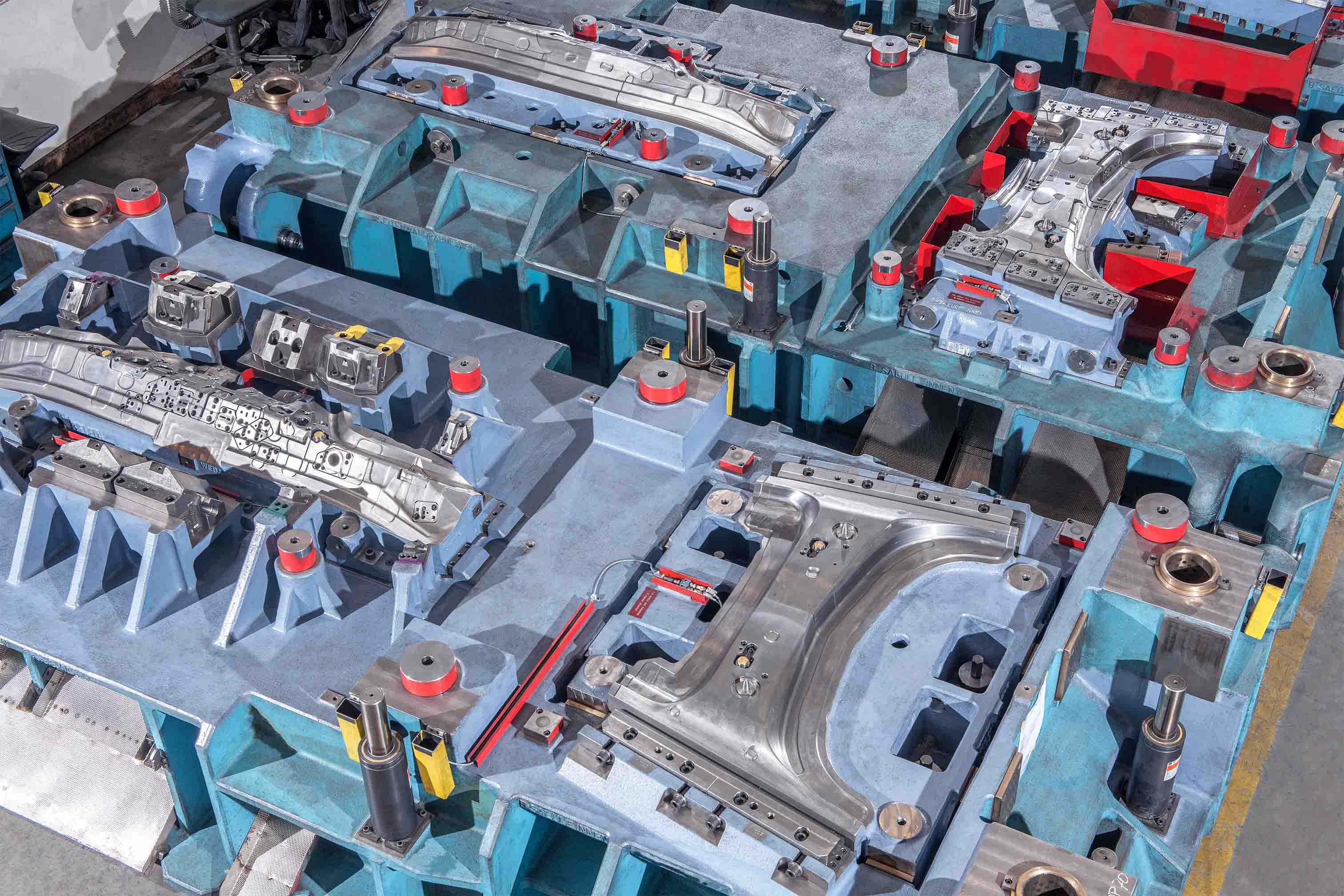

A tandem die works differently:

Here, the individual process steps are divided into separate dies, each mounted on its own press – arranged one after another in a line. This is why it is also referred to as a press line.

The material or part is transported by robots or gripper systems that move it from one press to the next. Each step – for example, preforming, deep drawing, or trimming – is carried out in its own die at a separate station. Where technically feasible, multiple operations can also be combined in a single stage, such as trimming and reshaping. To increase output, tandem dies can be designed for multiple-part production, sometimes even with different parts, provided the press size and capacity allow it.

This offers maximum flexibility for large components, complex geometries, or when forming processes need to be deliberately separated and precisely controlled.

Where are tandem dies used?

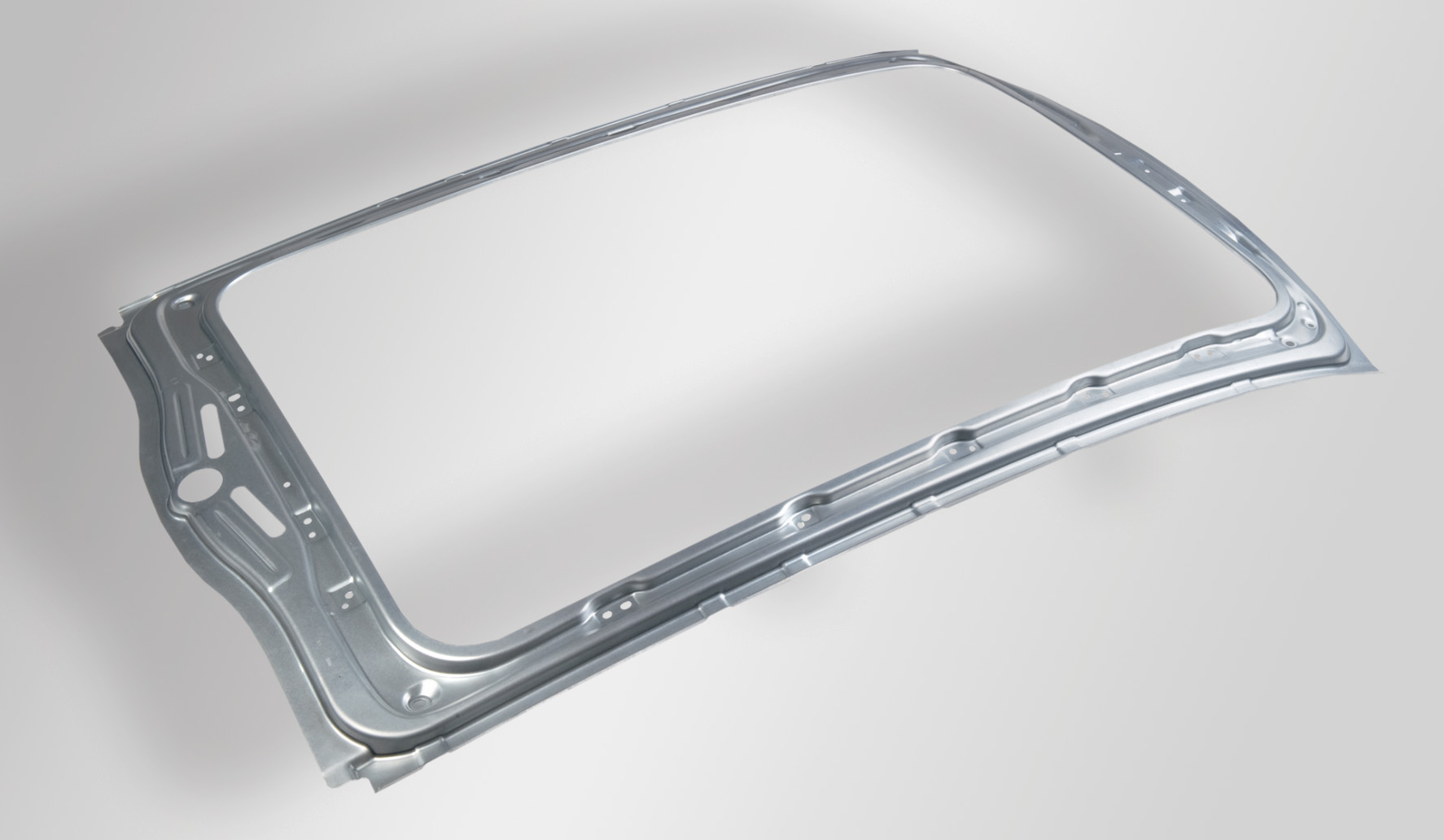

There are components, such as a car side panel, that are either so large or have such deep draw depths that they cannot be produced in a single forming stroke. This may be due to the limited bed size of presses or the fact that certain forming steps can only be carried out separately with specific parameters.

Typical reasons include:

- Component size: The part is too long, too wide, or too tall for a compact transfer die set.

- Complex geometry: Freeform surfaces, tight radii, or special draw contours require more space and separate stations.

Advantages of a tandem die

- Flexibility: Adaptable to part size and process design

- Modular design: Changes or adjustments are easier to implement

- Process reliability: Each step can be checked and optimized individually

- Suitability: Ideal for medium to small series or prototypes

Tandem dies are the method of choice when conventional transfer dies reach their limits. They enable economical and reliable cold forming in multiple steps – perfectly tailored to large, complex, or highly demanding components.

And that is exactly what weba Werkzeugbau stands for: well-conceived, practical solutions that turn challenges in forming technology into reliable series production processes.