History

THE HISTORY OF WEBA: FROM PIONEER TO RENOWNED LEADER IN HOT FORMING

The success story of weba began in 1982 in Dietach. After building a solid reputation, weba founded a subsidiary in the Czech Republic in 1990, specializing in the development of hot forming tools. These tools became the cornerstone of the company's growth, allowing weba to enter new markets. Over the years, weba expanded its capacities, invested in research and development, and solidified its position as a leading provider of hot forming tools. The history of weba is marked by hard work, passion for technology, and pursuit of excellence.

2025

weba Deutschland GmbH

Takeover of an existing production plant in Paderborn with 38 employees and the founding of weba Deutschland GmbH. The new site specializes in optimized solutions for sophisticated prototypes in the automotive, agricultural machinery, defense, and special protection vehicle sectors.

2024

DIN ISO 45001 Certification

Successful attainment of the DIN ISO 45001 certification for occupational health and safety management. This certification confirms weba's commitment to the highest standards in workplace safety and health protection, highlighting the focus on ensuring safe working conditions for all employees.

2024

Upgrade to 3DExperience onCloud and Introduction of DigiLab

With the upgrade to 3DExperience onCloud and the introduction of DigiLab, weba is taking another significant step towards digitalization and efficiency enhancement. DigiLab leverages cutting-edge artificial intelligence to analyze diverse data sources and generate automated reports.

2021

Joining and Welding Technology / IATF 16949 / Serial Laser

Investment in Gatzsch Schweißtechnik GmbH, which represents our presence in the field of welding technology.

Achievement of IATF 16949 certification and acquisition of a serial laser with two industrial robots for 3D part cutting.

2020

Multi-Machine Robotic Automation

To optimize our machining tasks and enhance automated processing, we have invested in a multi-machine automation system with linear handling.

2019

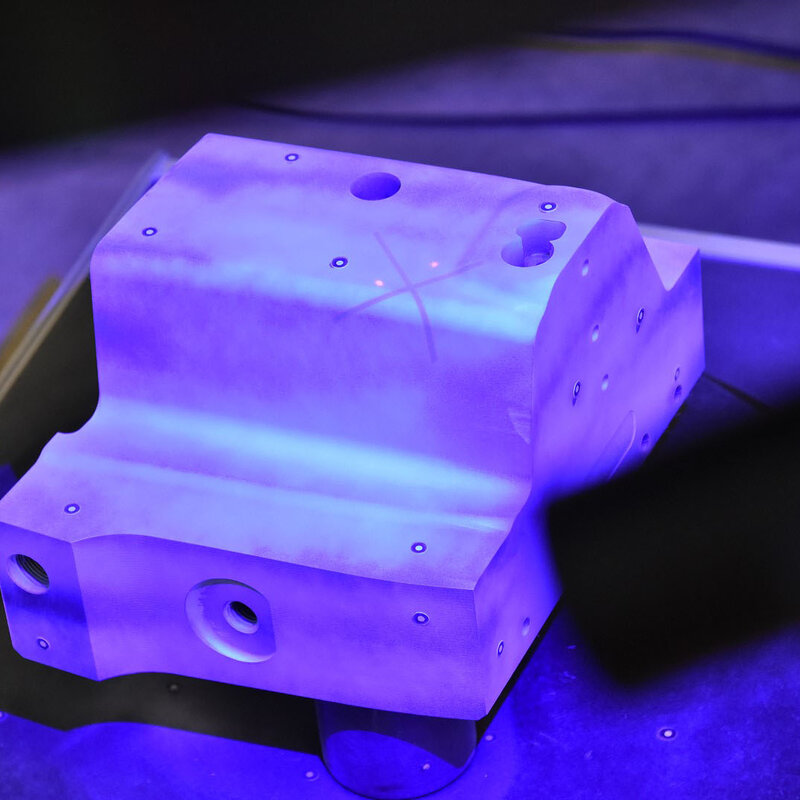

Digitalization of the Hot Forming Process

With SmartTools and advanced process monitoring, we have digitalized the hot forming process, allowing for more precise, efficient production and reduction of scrap.

2018

Expansion and Serial Production

Expansion of the production site in Olomouc from 4,200 m² to 13,000 m², and acquisition of a second automated hot forming line for optimal tool adjustment and flexibility in serial production.

2015

ISO 14001

Our ISO 14001 certification demonstrates our commitment to environmentally friendly practices and the continuous improvement of our environmental performance.

2013

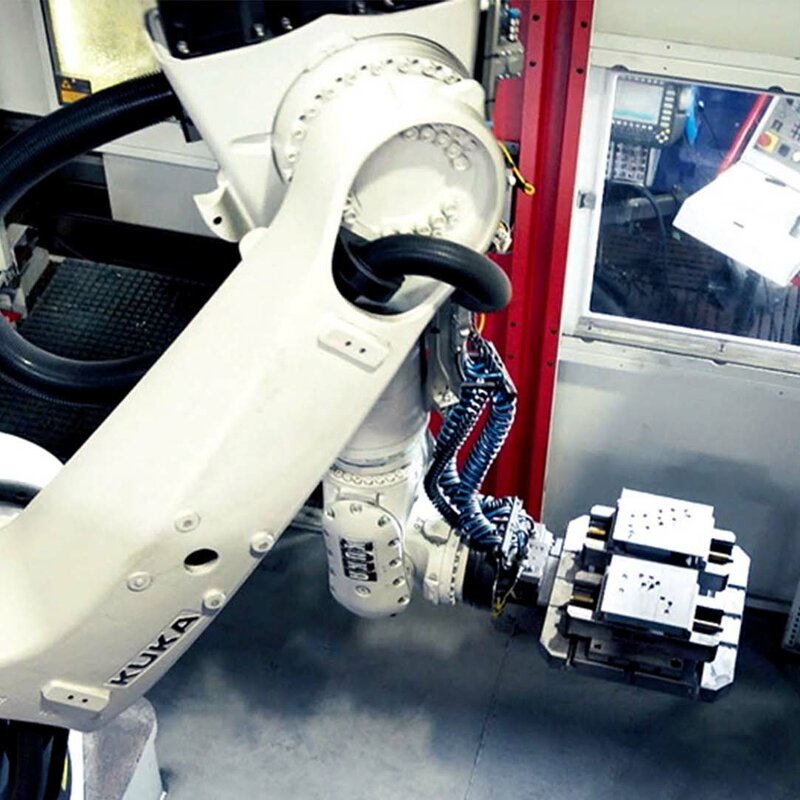

Automation in Machining Technology

The automation in 5-axis machining reduced setup and programming times, increased efficiency, and enabled longer unmanned operation.

2011

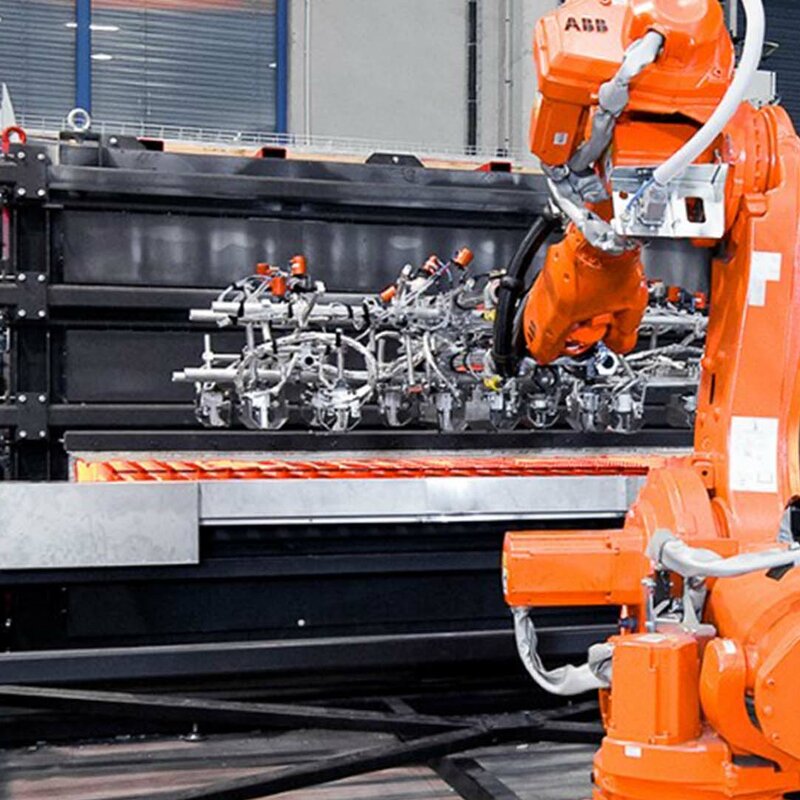

Automation of the Hot Forming Process

Acquisition of a 1,200-ton press with chamber furnaces and robots for the automation of the hot forming process.

2002

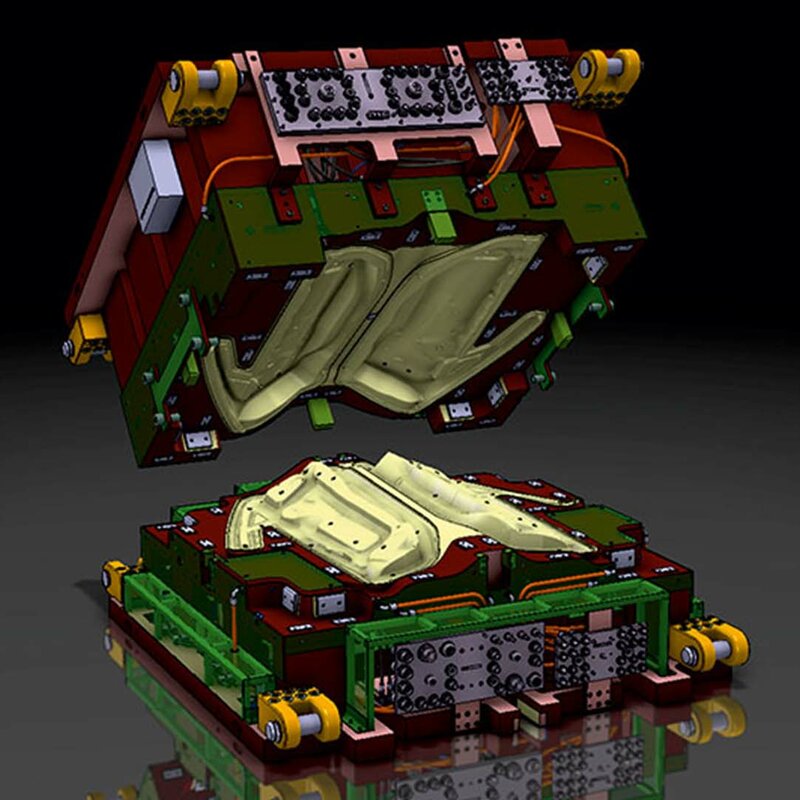

Implementation 3D Design

Implementation of 3D design to enhance product visualization, make development more efficient, and enable seamless integration into modern manufacturing technologies in production.

2001

New Plant in Dietach

Construction of a new production facility in Dietach, 5,000 m².

1995

Initial Certification ISO 9001

Our initial certification according to the standard ISO 9001 was a significant step towards quality management and continuous improvement.

1994

Hot Forming

As early as 1994, weba produced the first hot forming tools for the automotive industry.

1990

Foundation of the subsidiary in CZ

In 1990, weba established another production facility in the Czech Republic.

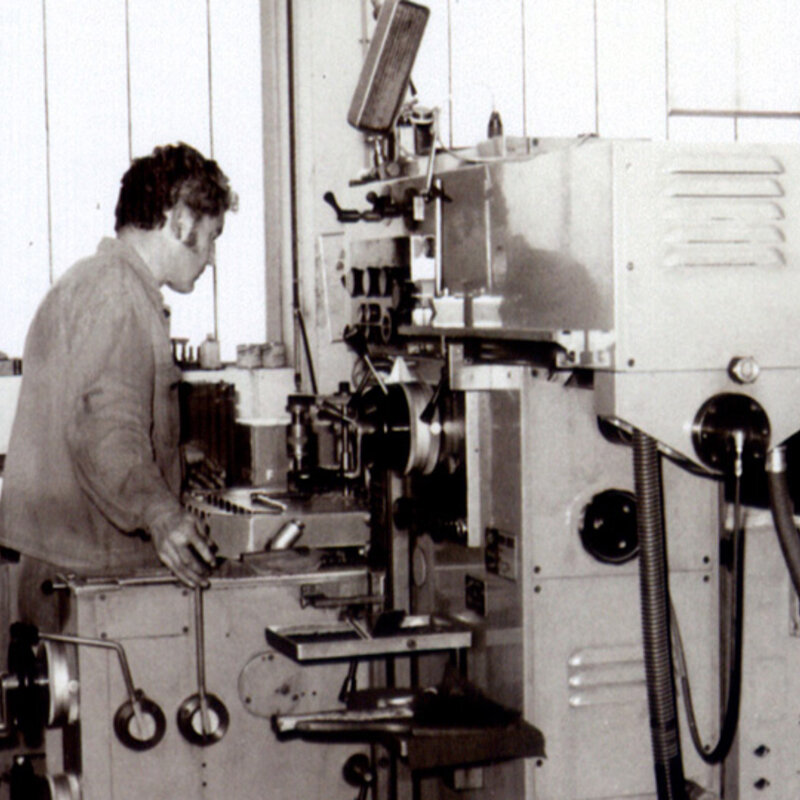

1982

Company Found

The weba story began with three technology enthusiasts from Dietach. In 1982, they decided to use their shared interest and founded weba Werkzeugbau in Dietach/Steyr.